When you’re catering for multiple customers, with multiple products, in multiple packaging formats, flexibility becomes the most important tool you have – especially in secondary packaging

Consumers drive retailers, who in turn drive manufacturers, who then drive their suppliers – it’s a story as old as industry. In some markets, the relationships are linear and not particularly broad, but in others, the hierarchy spreads like a tree’s roots, getting wider and wider the further down the supply chain it goes.

Massive product variety

A case in point is the pet food industry, which has undergone a renaissance in recent years. It used to be just five flavors of unappealing meaty chunks in 400g tins. That was it! Now, it offers multiple flavors, packaging formats, and sizes, providing ample choice for consumers and their pets. This demand for variety means supermarkets seek the best-selling and most appealing combinations of flavors, styles, sizes, and counts. This feedback flows to producers, who must constantly redevelop lines and styles, and then demand the means to package these varieties from packaging machine suppliers. It’s not easy!

Market driven

Gunnar Hallmann, Group Strategic Project Manager at C&D Foods, explains, “We are very market driven… we have to be! Customer demand for new formats and better packaging is fed to us by both consumers and supermarkets for whom we make own-brand pet food. Our value statement to them is ‘It’s our product—but Your Brand.’ We depend on each other for our success.” “It’s hugely competitive,” he continues, “and to keep pace, we continually invest in our products, people, processes, and packaging machinery. To maintain our hard-fought competitiveness, we need high-speed, high-technology, high-flexibility packaging solutions from machinery that delivers all the time, without issue or downtime.” C&D Foods purchased its first Cama Group machine in 2004 for its production facility in Longford, Ireland. In 2010, another installation followed, with more at other production sites – it has seven across Europe – in 2013/4. One of its most recent investments is for its Esbjerg plant in Denmark, for packaging 300g alu-cups, shallow square trays with foil lids.

Single solution to replace two machines

“The plant in Denmark is C&D’s main site for producing alu-cups, with different sizes filled and packed on site,” Hallmann explains. “But we had upgraded the filling capacity for 300g cups, and the two existing machines for different formats were reaching end of life. We tasked Cama with creating a single-plant solution that could do the job of two older machines, with greater throughput and flexibility.”

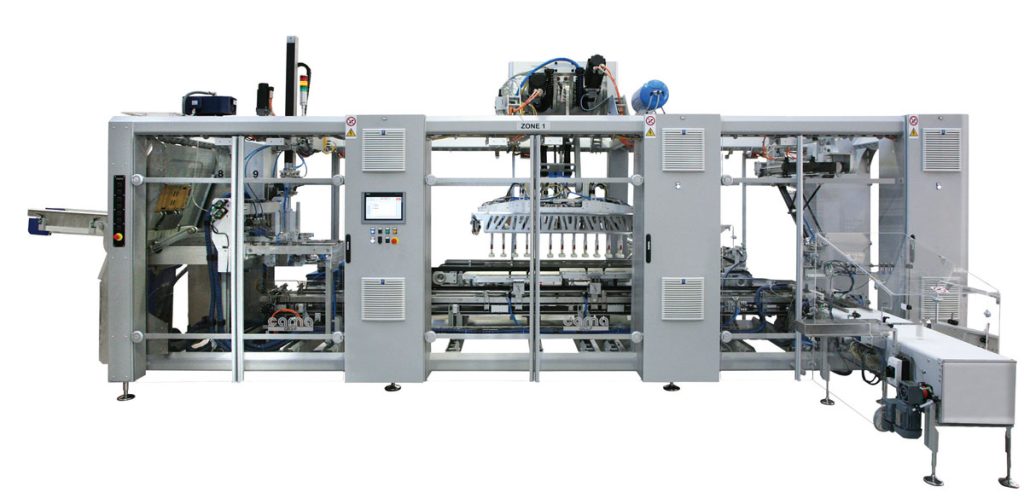

Cama’s solution comprised two IF series monoblock loading units with a box-forming machine and robotic loading unit. The IF series is based on the company’s modular Monobloc architecture, offering users a unique combination of integrated packaging machines and robotic loading units. Through tight integration of each primary module (forming, loading, and closing), Cama developed a machine delivering the flexibility demanded by the pet food industry within a reduced footprint. This secondary packaging solution catered to multiple packaging formats, with different product counts (6/9) and rows (1/2/3), in various tray/tray+external lid combinations. In operation, cartons are formed and glued, passing to an outfeed transport conveyor under the main line. The filled alu-cups arrive on two lanes and feed into loading units. The products are phased at the infeed of each loading unit by two star wheels and move into two pairs of vertical race-track pocket conveyors, with a single product in each pocket; these pockets are moved intermittently based on the loading pitch until the carton/tray loading configuration is obtained.

Advanced robotic technology

The grouped products are collected by a two-axis robot with a specially designed gripper and loaded into previously erected trays/hood cartons, phased by box-phasing units. Loaded packages are then transferred outside the loading unit, conveyed to a coupling/merging unit where trays are glued together (two or three trays). The coupled trays are then conveyed to a by-pass conveyor to the customer’s palletising unit or the lidding station. Trays with lids are diverted onto the conveyor and phased long-side leading toward the lidding machine, collected in a mono-axis phasing conveyor and positioned under each lidding head. The lid blanks are taken from the magazine and applied by a two-axis robot with four dedicated lidding heads. An open-flap detection system rejects any carton/lid with an open flap to a separate ejection station. IF series machines are part of Cama’s Breakthrough Generation (BTG), setting the standard in secondary packaging. They comprise modular, scalable frameworks that offer easy entry and access, coupled with a hygienic design. Within this framework, contemporary automation solutions, including advanced rotary and linear servo technology, are tightly coupled to in-house-developed robotics, delivering the flexibility and adaptability required by modern packaging operations.

Bespoke solution

“This was a tailor-made solution,” explains Renato Dell’Oro, Area Sales Manager at Cama. “It took time to design, build, and install, particularly fabricating some innovations that looked great on paper. It was the first time we’d gone into such detail. The complexity was significant, but necessary for the flexibility the customer required. Knowing these challenges, we ensured the customer had the same technical and sales team throughout the process.” Hallmann agrees, “It was challenging, compounded by the need to find the optimum layout based on the real estate in our Danish plant. From initial contact to machine start, we faced multiple hurdles, but Cama never gave up, pursuing all issues until resolved, all within the bounds and costing of the original quote. This was vital! I doubt other companies would have done the same.”

Good feeling and good technicians

“When we tender for packaging machines,” Hallmann continues, “we always ask multiple companies, with many discussions and solutions. We narrowed it down to two, but Cama’s layout and packaging solution best fit our needs. There’s a good feeling about Cama as a company. We have a full-time project manager supported by great technicians, and the same technical team all the time. Unlike other suppliers, the Cama sales team stuck with us until the project was finalized, not just until we signed the order.”

Dell’Oro concludes, “C&D Foods supplies many supermarkets with own-brand products, making packaging variety immense. Flexibility is essential! They were early pioneers in multi-tray packs, a concept now universal across the industry. Despite the variety, changeovers are simple, as only the carton/lid forming and closing heads need changing, which are quick-release, and the HMI adjusts the software parameters. The pockets on the racetracks remain unchanged. It was challenging, but at Cama, we believe ‘you achieve by doing,’ and always go further, which is why we win repeat orders.”