Industry 5.0 reframes manufacturing around human-centric collaboration with intelligent machines, combining productivity with environmental responsibility. In secondary packaging, Cama Group is translating this vision into practical value by evolving machinery, software, and services that improve changeover times, process stability, quality, and energy efficiency across the line. The company’s approach aligns with the European Commission’s framing of Industry 5.0 and places operator experience, safety, and sustainability at the core of innovation.

Human + Machine, by design

Rather than replacing people, the goal is to pair operators with collaborative technologies that remove repetitive work and reduce cognitive load, so teams can focus on activities that differentiate the customer experience. Cama describes this as “making sophisticated systems simple,” using interfaces, contextualised language, and shared goals to close the gap between humans, robots, and AI. The result is a cultural shift: lines become easier to operate, training ramps faster, and knowledge is embedded into the machine itself.

AI & GenAI where it matters: code and compliance content

AI—and especially Generative AI (GenAI)—has moved from curiosity to everyday tooling. On the software side, Cama is rethinking programming so that repetitive code writing is automated, letting engineers focus on higher-value tasks like architecture, quality, and safety. In technical publishing, GenAI helps draft manuals, risk analyses, technical files, and declarations of conformity within a structured, data-rich knowledge base, accelerating delivery while maintaining human oversight. The impact: fewer errors, more standardised content, and higher productivity in documentation-heavy workflows that typically slow projects down.

Data-driven efficiency: mastering environmental variables

Packaging performance is not only a function of the machine; it depends on ambient humidity and temperature, material properties, and settings across the line. Cama’s R&D studies machine data in depth to map correlations between operating parameters and outcomes—for example, how seasonal humidity shifts affect machinability and packaging quality or how temperature accelerates component wear. Turning these relationships into actionable guidance allows better presets, predictive adjustments, and fewer stoppages, raising overall line stability and OEE.

The Machine Enhancement Program (MEP)

Cama’s Machine Enhancement Program is a scalable platform—available for new builds and retrofits—focused on saving materials, energy, time, and space. It is designed to deliver fast adoption and tangible improvements in format changeover, process quality, and production continuity. Today the program includes five fully operational systems—Augmented Reality guidance, Digital Twin, Automatic Format Changeover, Automatic Carton Loading, and Collaborative Palletising—with two advanced modules in development.

1) Augmented Reality (AR) work guidance

AR is now standard on new machines (and retrofittable on most recent bases). Operators scan QR codes on specific areas to access a digital environment with step-by-step procedures, 3D animations, targeted checklists, and contextual documents. Compared with static manuals, AR reduces errors, shortens learning curves, and helps teams perform complex tasks confidently. Training can be done in front of the machine in virtual mode or via VR without stopping production—accelerating onboarding and raising first-time-right execution on the shop floor.

2) Digital Twin for design, validation, and what-ifs

The Digital Twin simulates vision systems, picking logic, quality control, and product behaviour across the cycle, so engineering can validate cycle time, picking feasibility, and flow consistency before building physical prototypes. It also makes it easy to test format variants and edge cases, compressing timelines and reducing risk during FAT/SAT and early production. In practice, this means fewer surprises at start-up and a clearer, data-based path from concept to performance.

3) Automatic Format Changeover: push-button performance

Human error and changeover-related downtime are among the biggest pain points in packaging lines. Cama’s fully automatic format changeover addresses both: choose the recipe, press a button, and the machine adjusts itself. In day-to-day operation, this typically halves changeover time versus manual procedures and sharply reduces setup mistakes, which is crucial wherever staff turnover is high and teams change frequently. Beyond time saved, standardised changeovers also stabilise quality and reduce waste during ramp-up.

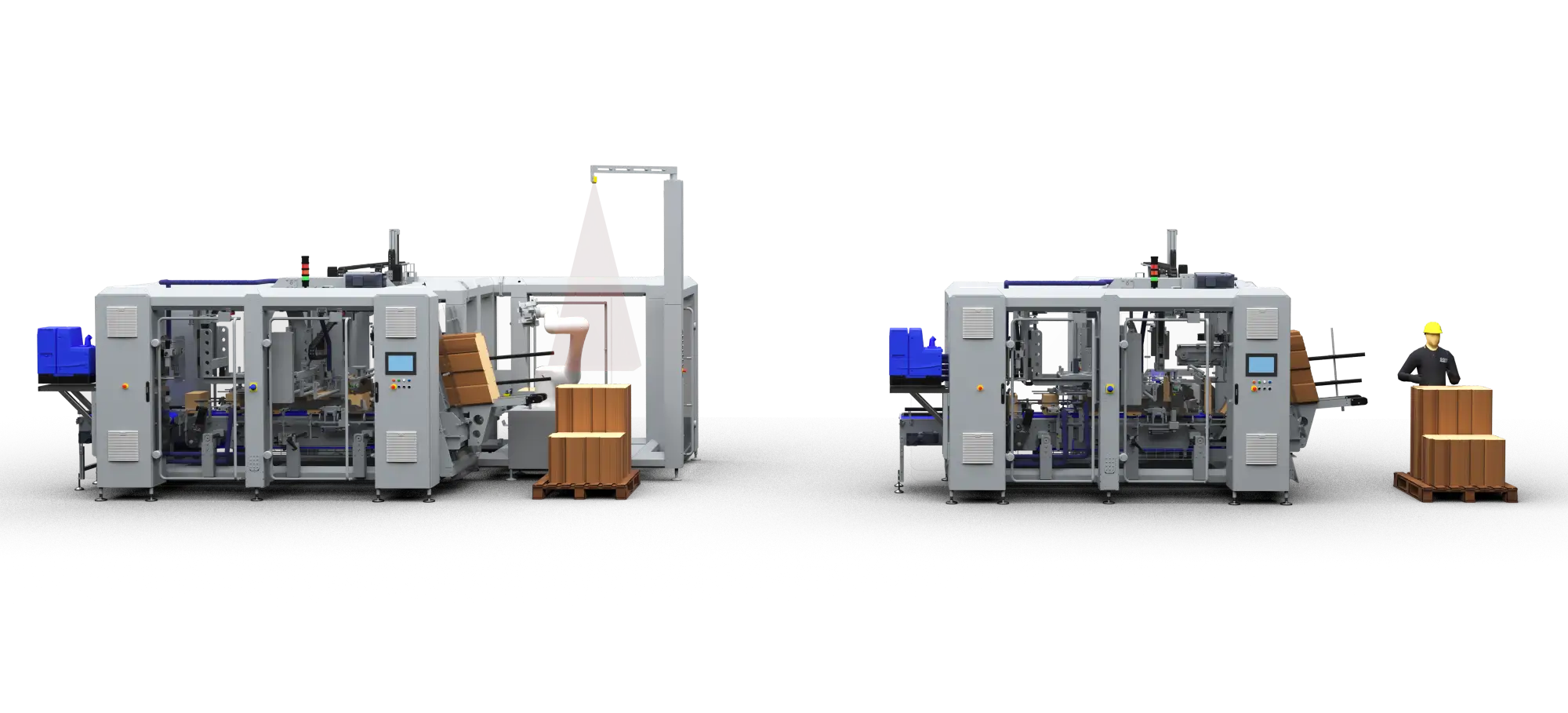

4) Automatic Carton Loading: stable magazine, stable line

Previewed at Ipack-IMA (May 2025), this system uses a collaborative robot to pick die-cut blanks from the pallet and feed them into the magazine. The impact is felt immediately: the magazine is no longer a bottleneck; the cobot keeps the flow constant, reduces micro-stops, stabilises the cycle, and preserves cardboard quality thanks to repeatable handling. By removing a frequent manual chore and normalising input quality, the whole end-of-line becomes smoother and more predictable.

5) Collaborative Palletising: natively integrated

Collaborative palletising is not a new concept, but Cama’s edge is native integration with the case packer, enabling transparent communication between systems. That integration streamlines hand-offs, alarms, and recovery logic, helping operators diagnose issues faster and minimising stop-start friction at the end of the line. As a result, palletising contributes to a more continuous takt rather than becoming an island of automation.

In development: AMR logistics & Edge Computing intelligence

Two additional capabilities are in advanced development:

- Autonomous Mobile Robots (AMR) for long-distance pallet handling—from warehouse to machine—boosting line autonomy and reducing manual traffic around production cells.

- Edge Computing, which turns machine-generated data into reliable, real-time insights for stable processes, faster diagnostics, and higher design standards on next-generation machines.

Both will be on display at Interpack 2026 (Düsseldorf), underlining Cama’s trajectory toward more autonomous, data-smart secondary packaging systems.

Why this matters for manufacturers

Across the program, the combined effect is compelling:

- Higher productivity through faster changeovers, fewer micro-stops, and smoother end-of-line flow.

- Lower waste and energy consumption via better presets, stable magazine feeding, and data-backed adjustments.

- More consistent quality thanks to AR-guided procedures, digital-twin validation, and error-proof setups.

- Faster training and safer operations, with skills embedded into the machine and visualised “just-in-time.”

- Future-ready scalability, with retrofit paths and a roadmap that adds AMR logistics and Edge intelligence.

Implementation notes (for quick wins)

- Start with AR: it’s a low-barrier upgrade that immediately reduces errors and compresses onboarding.

- Use the Digital Twin during engineering changes and SKU expansions to de-risk format variants before trials.

- Automate changeover where SKUs and teams rotate frequently; the ROI is often clearest here.

- Stabilise inputs with automatic carton loading to cut magazine-related micro-stops.

- Integrate palletising natively to remove end-of-line choke points and unify diagnostics.

Conclusion

Industry 5.0 is not a slogan; it’s an operator-centered operating model that blends collaborative robotics, AI, and data into everyday packaging work. With its Machine Enhancement Program, Cama Group offers a pragmatic path to productivity, sustainability, and resilience—in new lines and retrofits alike. To explore modules, case studies, and deployment options, visit camagroup.com.