Advanced packaging solution integrates seamlessly into modern component fabrication line thanks to innovative in-machine and between-machine transportation technology

Cama Group prides itself on its innovative approach to design, development, and deployment of new technologies, aimed at enhancing integration, throughput, accuracy, and quality within the packaging industry.

Cama’s machines operate globally in a diverse range of packaging applications, blending modular, accessible, and hygienic mechanical frameworks with the latest automation technology. This includes advanced and tightly integrated in-house-developed robotic pick-and-place solutions.

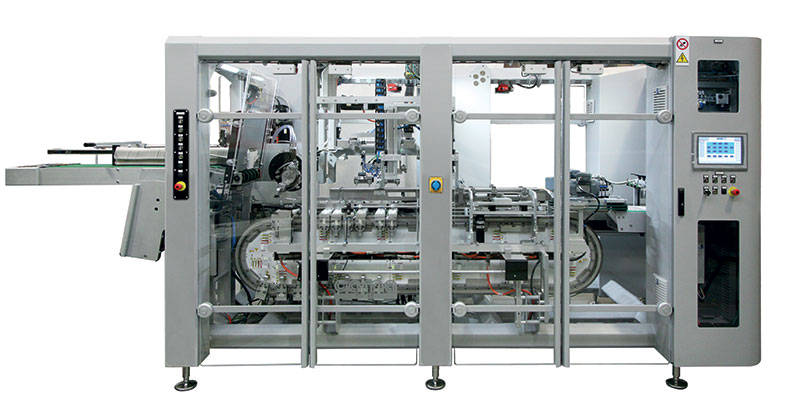

In a recent project, Cama’s technological expertise was put to the test when tasked with designing and integrating one of its Breakthrough Generation (BTG) CL 175 cartoning machines into an electrical component fabrication line at Rockwell Automation, one of the world’s largest automation vendors.

Beyond proving the integration capabilities of the control solution, Cama had to ensure its machine fitted seamlessly into the rest of the line, much of which was developed and built by Calvary Robotics, a US-based specialist in automated assembly, testing, and material-handling systems.

Giovanni Panzeri, Automation Project Leader at Cama, explained, “The line with which we were integrating is designed for assembling a wide range of contactors, varying in model type based on contact configuration, voltage, and certifications such as CE and UL. The line is highly flexible, allowing for small batches of various contactor models to be fabricated just-in-time, with minimal re-engineering and downtime. Our packaging solution had to match this level of flexibility to adapt and respond to varying product throughputs.”

Cama and Rockwell Automation had previously collaborated on several industry-leading packaging machines, establishing a strong foundation. Cama’s experience with Rockwell’s independent cart technology (ICT) helped seal the deal, providing a crucial link to the rest of the line.

“Cama was one of the first companies to deploy the iTRAK ICT in a customer application,” Panzeri notes, “so we had a good understanding of how it could be leveraged to deliver the flexibility many end-users require. The individual product carriers in our machine, controlled by the central PLC, are automatically adjusted based on the product’s width or product groups, enabling the cartoner to operate intermittently or continuously, depending on throughput needs.”

“The CL 175 has three main operating stations,” he continues. “First, carton boxes are picked from a magazine, opened out, and placed into pockets on the iTRAK carriages. Then, two boxes at a time are presented to the insertion station, where contactors are inserted. After insertion, the boxes are closed, sealed, and then proceed to a printing station where product-specific information is printed and verified before exiting on a conveyor. The iTRAK carriages recirculate under the track for the next round. This system uses a software interpolator to coordinate the iTRAK with servo pushers, enhancing accuracy and reducing mechanical stresses compared to pneumatic systems.”

“Advanced automation is second nature to us,” Panzeri adds, “thanks to our extensive experience with robotics and servo technologies. But a key element of this installation was integrating the CL 175 with downstream assembly processes to avoid bottlenecks, made possible by another Rockwell ICT technology: MagneMotion Lite.”

The Calvary Robotics line includes three assembly machines, a product-printing module, and two testing stations, arranged in a ‘U’. The MagneMotion ICT interlinks these, making it the ideal solution for extending into the packaging operation.

“Full integration was possible thanks to the Allen-Bradley’s control architecture,” Panzeri explains. “This creates seamless interactions across all line elements, with our packaging solution simply adding another step. Full EtherNet/IP connectivity across machines and I/O Link at the component level enables a transparent data flow, creating a true Industry 4.0 solution. The interconnected architecture also ensures harmony across the line, with each station ready for its task with minimal human interaction.”

Cama’s selection by Rockwell Automation attests to their strong partnership and reinforces modern integrated control solutions. “We often test new Rockwell hardware,” Panzeri notes, “and this line showcases three engineering teams working towards a common goal, underpinned by a powerful integration model.

“This line reflects our technology, teamwork, and capabilities, and illustrates the direction of the packaging industry,” Panzeri concludes. “ICT technology both in machine and between machines enables flexible production, turning production lines into production grids, where products visit only necessary stations, without mechanical complexity or transportation conflicts.”