Sustainable packaging challenges conquered with Cama’s expertise, at leading global home and healthcare manufacturer

There are many reasons why companies might seek to reinvent their packaging infrastructure and routines, including the need for higher speed, greater throughput, or enhanced flexibility. However, with modern legislation and current consumer sentiments in mind, sustainability has become the overriding factor. With single-use plastic broadly shunned globally, many companies are transitioning to recyclable materials, with cardboard being one of the most popular choices.

This shift, however, necessitates a comprehensive redesign—from primary product packaging materials and concepts, to new machines and plant layout configurations, to secondary packaging with new materials and designs, and all the way to final palletizing.

Easier, streamlined transition

Even for large companies, reinventing packaging can be a daunting task. However, for one leading global home and healthcare product manufacturer, Cama Group made the entire process significantly easier and more streamlined. This customer’s brands are recognized worldwide, and they must take the lead in sustainability efforts. In many markets, their products are packaged in secondary containers that also double as shelf-ready display cases. However, many of these contain plastic in their shells and the trays that orient the products. The challenge was to switch to a 100% cardboard packaging concept that opens quickly, displays easily, and maintains brand quality. This specific product was a self-administered cold remedy, but this challenge applies across the customer’s entire healthcare range and reflects a global issue in the home healthcare industry.

“In the first instance, we played a major role in a lengthy design exercise chaired by the customer, creating a new secondary packaging design and display concept,” explains Alessandro Rocca, Sales Engineering Director at Cama Group. “Unlike other companies, we have a highly experienced packaging design team within Cama that has created thousands of ideas over the years, from simple to intricate.”

Matching technology with space availability

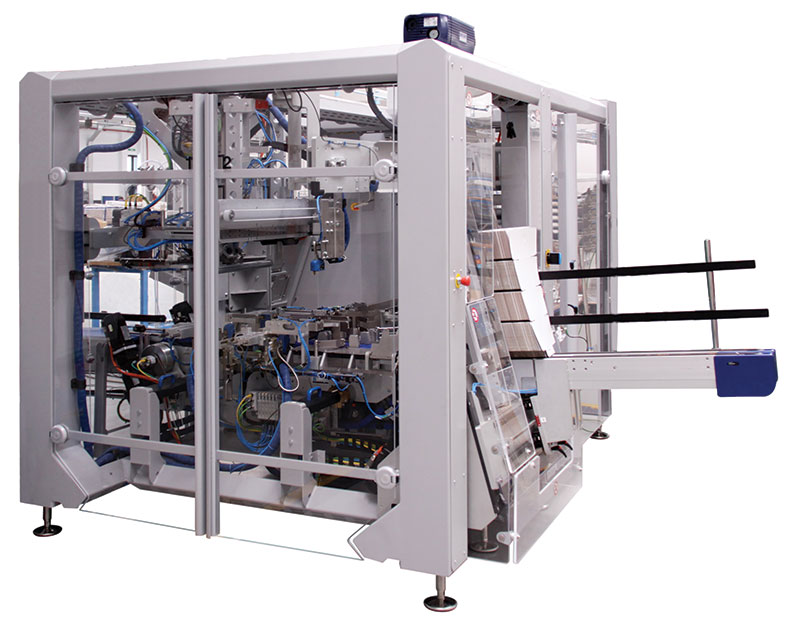

“After extensive testing and deliberation, the new design concept was finalized, taking into account packaging machinery capabilities,” Rocca explains. “Machinery plays a crucial role in design exercises, as multiple technologies exist. In this instance, a lack of factory real estate meant only certain machine types and styles could be deployed, helping to define the packaging design. Other companies suggested top-loading machines, but Cama’s new FW746 wraparound case packer, fresh from our research and development department, was the ideal solution, joining our class-leading Breakthrough Generation (BTG) series.”

Many of Cama’s competitors struggle to combine high-speed secondary packaging within limited space. The FW746 not only meets speed requirements repeatedly and efficiently, but does so in a machine some three meters shorter than its competitors.

The standard for secondary packaging

“The FW746 also benefits from being part of the BTG family,” Rocca explains, “which is setting the standard in secondary packaging. Their modular, scalable, and hygienically designed frameworks house contemporary automation solutions, including advanced rotary and linear servo technology, which can be tightly coupled to in-house-developed robotics, delivering the flexibility and adaptability required by modern packaging operations. The machine range is also based on a digital platform that supports full Industry 4.0 capabilities, including AR, VR, and virtual testing, training, and operation.”

“The actual packaging procedure was relatively simple, with a few twists,” Rocca elaborates. “We had to flip the products 180° prior to secondary packaging, creating a simple concept that delighted the customer’s engineers and was more reliable than complex ideas on the market. The customer also wanted a full traceability-and-checking system, to check, print, and verify the carton and its coding before it moved to the palletizer. This integrates with a network, linking the machine with upstream and downstream processes.”

“We are fortunate to have a strong relationship with this customer, having delivered packaging solutions to its various factories globally,” Rocca explains. “But this depth of understanding and trust, developed over years, doesn’t mean we take it for granted. Whether the first order or the 100th, we put the same amount of effort, dedication, and expertise into every job, conscious of competitors envious of our reputation and technology.”

“Although this was a standard packaging request, we devoted significant resources to this project, including our packaging design team, to ensure a fully satisfied customer,” Rocca concludes. “You might think it fortunate that we had a machine fitting the application perfectly, but it wasn’t luck. We study the market and anticipate its needs, and the proactive introduction of the FW746 is just part of the future of modern packaging demands.”