Cama Group redefines CPG and HPC packaging practices, with modular, high flexibility, fully automated packaging solutions that can deliver multiple shelf-ready formats with minimal costly and time-consuming re-engineering

As consumer preferences and marketing promotions demand a broader variety of product offerings, many leading consumer packaged goods (CPG) and health and personal care (HPC) companies are seeking significantly more flexibility and agility from their OEM machine suppliers. Traditionally known for its strength in the confectionery and bakery sectors, Cama Group has applied its packaging expertise and technology to the CPG and HPC domains, providing shelf-ready packaging solutions that outperform those offered by many traditional industry suppliers.

Alessandro Rocca, Sales Group Director at Cama, notes, “In the homecare market, there is a trend towards higher in-feed and box speeds, which often do not align with the need to create packaging that also has strong visual appeal. This style of shelf appeal has always been crucial in the food sector, and as a result, this type of packaging format is much more advanced. Indeed, many CPG and HPC companies are now turning to food industry suppliers like Cama, who can provide machines that work from blanks and ultimately deliver impressive shelf appearance.

“High output and flexibility aren’t strong points for traditional suppliers either,” he continues. “In those cases, packaging in bulk and mass shipping have typically been prioritized over aesthetics. We see similar opportunities in other markets and products, where speed combined with appealing visuals is beginning to shape future strategies.” Cama has recently collaborated with a leading global HPC brand to develop an aerosol can packaging solution that encapsulates all the key elements of this modern approach: speed, agility, flexibility, meticulous product handling, and, importantly, shelf-ready packaging.

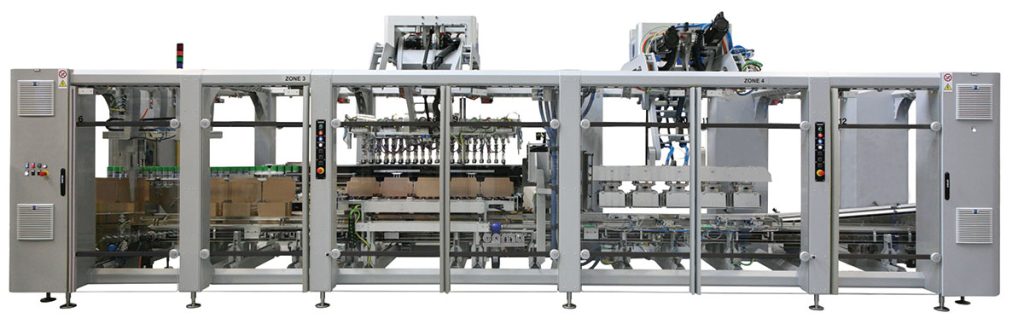

The Cama IF series, built on the company’s award-winning modular Monobloc architecture, offers a unique combination of integrated packaging machines and robotic loading units. By tightly integrating each of the primary modules—forming, loading, and closing—Cama has engineered a machine that not only meets the demanding flexibility required by the HPC industry but does so within a compact footprint.

Close Collaboration

“We worked very closely with the customer on the design and realization of this variant,” Rocca explains. “It was part of an internal development project aimed at addressing rapidly changing market demands—both in terms of product variety and the ensuing changes in packaging formats—without compromising on quality or visual appeal. The customer still required high throughput, however,” he continues, “so we leveraged our expertise from other industries and applied it to a machine that we believe will redefine packaging in the CPG and HPC sectors going forward.”

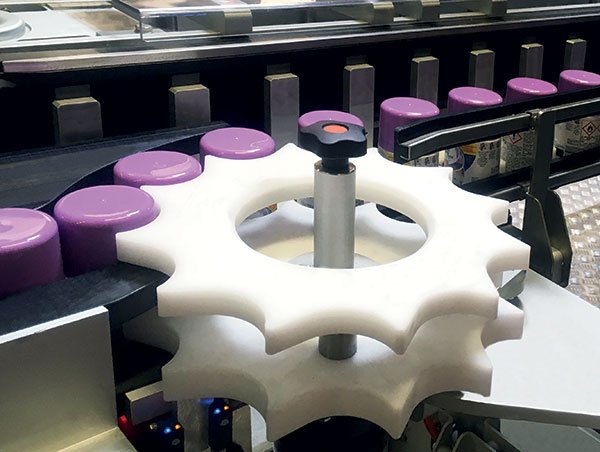

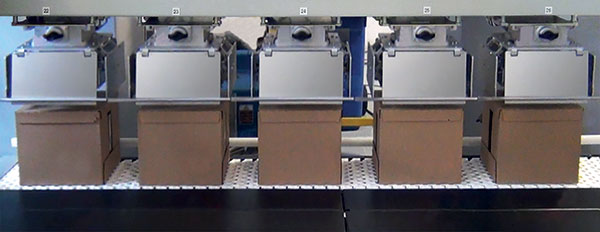

In operation, the machine processes capped aerosol cans from an infeed system, assigning each can to a separate feed pocket to maintain separation and ensure precision and control—key tenets of Cama’s product handling philosophy. Boxes for the aerosol cans are simultaneously formed on a machine capable of accommodating a diverse range of product counts, diameters, and heights. Following this, the cans are picked up individually—or in groups as specified by the packaging recipe—by a custom multi-format gripper, developed in collaboration with the customer. A Cognex camera-based vision system performs quality control checks on product count and cap quality before the boxes move to a closing station to complete the packaging process. “Each individual gripper can be adjusted,” Rocca elaborates, “which means minimal re-engineering is required when product formats change. This adaptability and quick changeover are reflected across the machine’s other modules, allowing it to manage 14 different box configurations and numerous product formats.”

Advance Automation

“Tightly integrated automation is what sets us apart,” Rocca enthuses. “The majority of the axes control is handled by servo motors. These solutions are complemented by our proprietary two-axis robotic loading technology, designed in-house to sync perfectly with our machine’s operational parameters. Clients have the option of integrating either Rockwell Automation or Bosch automation solutions, enhancing the machine’s integration into broader enterprise systems. In this case, a Rockwell Automation control architecture was implemented, supported by comprehensive training provided by the automation supplier to the customer. The culmination of all this development work and close collaboration with the end user is a machine capable of gently and accurately packaging a wide variety of products into shelf-ready formats at speeds up to 60 boxes per minute—a rate significantly higher than what Cama’s competitors can offer. We have established remarkable references within the CPG and HPC industries for multi-variety product packaging,” Rocca continues. “Key to our approach is flexibility, combined with the capability to produce shelf-ready cases and maintain high line output. We are well-equipped to tackle any Industry 4.0 and IIoT initiatives, as our control solutions seamlessly connect to plant-wide systems. In addition, we are enhancing our design capabilities by developing virtual commissioning and digital/virtual twins, alongside our bespoke software and control applications that ensure robust cybersecurity while interfacing with higher-level control systems.”

Global Capabilities

“The customer approached us because, like them, we have a global footprint, with offices around the world,” Rocca concludes. “They realized that if their own supplier base couldn’t provide the technology and solutions they needed, they would have to look elsewhere; this brought them to us. We have since entered into a global agreement to supply technology to their other plants. Our experience across multiple industries enriches our knowledge, allowing us to continually evolve and enhance the services we offer to our clients.”

“The customer approached us because, like them, we have a global footprint, with offices around the world,” Rocca concludes. “They realized that if their own supplier base couldn’t provide the technology and solutions they needed, they would have to look elsewhere; this brought them to us. We have since entered into a global agreement to supply technology to their other plants. Our experience across multiple industries enriches our knowledge, allowing us to continually evolve and enhance the services we offer to our clients.”