Leading pet food company looks to Cama to develop flexible packaging solution that easily adapts to market needs and consumer trends

A fast growing petfood manufacturer from UK has gained a reputation for high quality wet petfood that has allowed it to grow sales in global export markets. Following a recent investment in the process and filling side for pet food trays, the pressure was building to reduce costs and increase throughput on their packaging line. The problem was that its customer’s wanted standard single unit items and increasingly multi-pack, multi-flavour packaging; two very different packaging formats. It is existing equipment was slow and the process for the complete range of products required a lot of manual labour.

Flexible solution

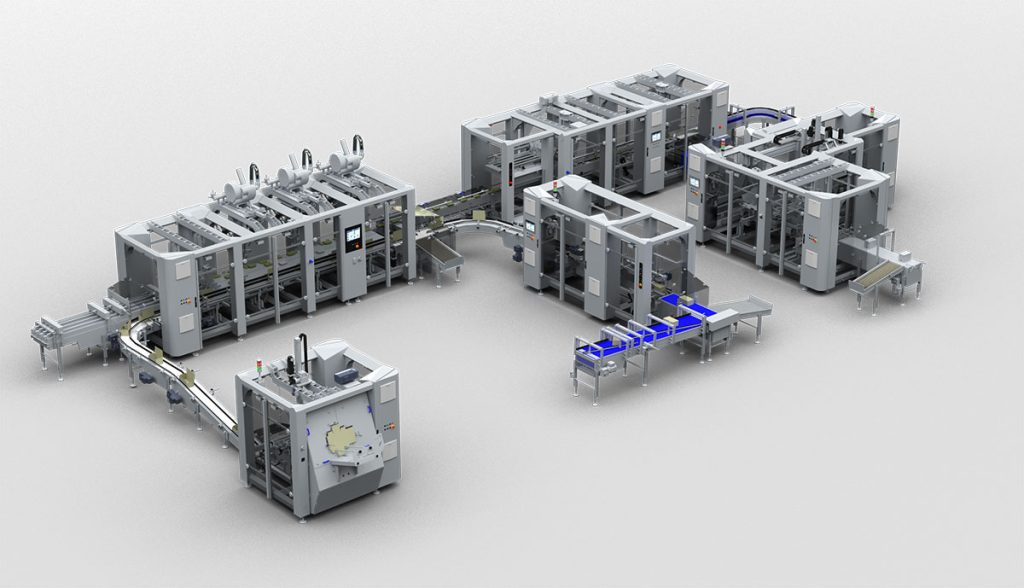

The brief to Cama was to provide a solution that could deliver sleeved single trays in display cases for single-unit purchases and also multi-pack variants, with up to four different flavors in a consumer-friendly take-home box. This flexibility is further extended to cope with different tray and pot sizes ranging from 85 to 400g (3 to 14 oz) . Thanks to Cama’s decades of experience providing packaging machines and its in-house packaging design team, Cama proposed a concept incorporating box forming and loading, sleeving, case packing, bundling, and palletizing to create a full turn-key system. Working with its partners, Cama integrated inkjet coding, print-and-apply labelling, and barcode scanning to ensure the whole system met the customer’s need to adhere to regulatory requirements for labelling and traceability of meat products.

Multi-format capabilities

The key to the line’s flexibility is Cama’s vision-driven IG delta robot cell, incorporating four Triaflex robots that take products arriving in four lanes and either load the infeed of the sleeving machine for single-unit sales or load directly into a take-home box. All products run at 200 trays per minute. When running multi-flavour, the infeed lanes are allocated to a specific flavor, and the relevant box configuration is packed by the robots as the boxes travel through the IG loading unit.We now have some excellent references in the CPG and HPC industries, including multi-variety product packaging applications. Flexibility is key, combined with shelf-ready cases and high line output. We can also easily address Industry 4.0 and IIoT initiatives, as the control solutions we deploy offer seamless connection to plant-wide systems. To strengthen our design capabilities and simplify life for our customers, we’re working on virtual commissioning and digital/virtual twins, alongside our software and control applications that communicate with higher-level control systems while delivering robust cybersecurity.

Industry 4.0 ready

Cama’s machines are seeing an incredibly positive reaction across many markets due to their flexibility, positive handling, and high efficiency levels. Thanks to highly capable robotics and advanced automation solutions, they are Industry 4.0 ready and will comfortably fit into any smart-manufacturing environment. And with a standardized solution, the end user realizes multiple benefits beyond operational performance. The consumer boxes are formed on Cama’s FA21 forming unit, with the lids left open, and pass to the loading for top-loading by the robots before being closed with hot-melt glue on a versatile CD56 top flap closing machine. Smaller boxes are collated and shrink-wrapped into bundles before palletising, while larger cases are fed directly to the palletiser. When running sleeved products, all four infeed lanes contain the same flavor, and the robots load the trays directly onto the flighted infeed conveyor for the high-speed Cama MP91 sleeving machine. A close-coupled Cama FW748 wraparound case packer receives the products at 200 trays per minute and packs them into Shelf Ready (SRP) wraparound display cases. As a result of this investment, the customer is now able to pack more than three times as much product per day, utilizing fewer people and reducing reliance on temporary workers. The greater efficiency gained from the investment will allow for a Return on Investment (ROI) within 2 years.