The switch from manual to automatic systems often requires packaging redesigns. But if you don’t have the luxury of being able to change, you need to call Cama, the secondary packaging experts!

Many convenience foods are no longer seen as a lazy shortcut to a simple meal. New varieties, flavors, and formats – coupled with challenging shopping conditions during the pandemic – have created a level of demand eclipsing other food and beverage formats. Instant noodles are part of this revolution. Historically a staple of local cuisines and students worldwide, they are now gaining ground as a regular shopping basket item in numerous new countries.

Some markets are well established, such as Japan and China, but India and Malaysia are also growing and even overtaking China. In these traditional and emerging markets, customers are spoilt for choice regarding flavors and varieties, with some formats constituting a full meal on their own.

This explosion in demand in newer markets hasn’t gone unnoticed by noodle manufacturers, who are now introducing additional economies of scale as operations ramp up to cater to this elevated demand. In many cases, these economies are realized through greater automation and digitalization within manufacturing and packaging processes.

Higher quality & repeatability

By eliminating irregularities and inefficiencies, and replacing them with higher quality and repeatability, manufacturers are seeing increased yield and throughput, ultimately boosting output and the bottom line. Alessio Borgo, Global Key Account Manager at Cama Group, explains, “In many cases, automation is used to replace what are often highly manual processes. Once output starts to rise, the argument for automation strengthens, as the extra flexibility and savings per product are easier to justify. It also enables companies to relocate employees to areas where they can have more impact.”

A recent project in South-eastern Europe exemplifies this, where a leading global food and snack manufacturer sought to automate its end-of-line secondary packaging operations for instant noodles.

European first

“This installation represented a first for this plant,” Borgo explains. “It was the first step towards a fully automatic case packing process, replacing manual packing. In fact, it was not only the first for this plant, but also the first for the company in the European market for this specific type of product. As a result, interest and expectations for how the Cama solution would meet plant and production requirements were high at all levels of the company.”

The new solution replaced an eight-operator-per-shift rotation that was erecting, filling, and closing RSC boxes containing flow-wrapped noodle packs. The pressures from increased output had been compounded by staffing issues during the pandemic, making it the perfect time to automate.

“When transitioning from manual to automatic operation, boxes often need to be adapted in terms of dimensions,” Borgo elaborates. “But in this instance, one key goal was to keep box dimensions identical to maintain current material and transportation costs. This was a real challenge, as there was no extra space inside the box to absorb any inflexibility.”

Close collaboration

“With these size constraints in mind, we had to approach the challenge on two fronts,” he continues. “First, we worked with the customer to identify the product variables that would impact the packaging arrays, and then we developed a cutting-edge solution with high adaptability, to absorb and equalize different product configurations and properly fit them inside the box. In fact, our attention to detail at the case-packaging stage had a ripple effect on further downstream process improvements.”

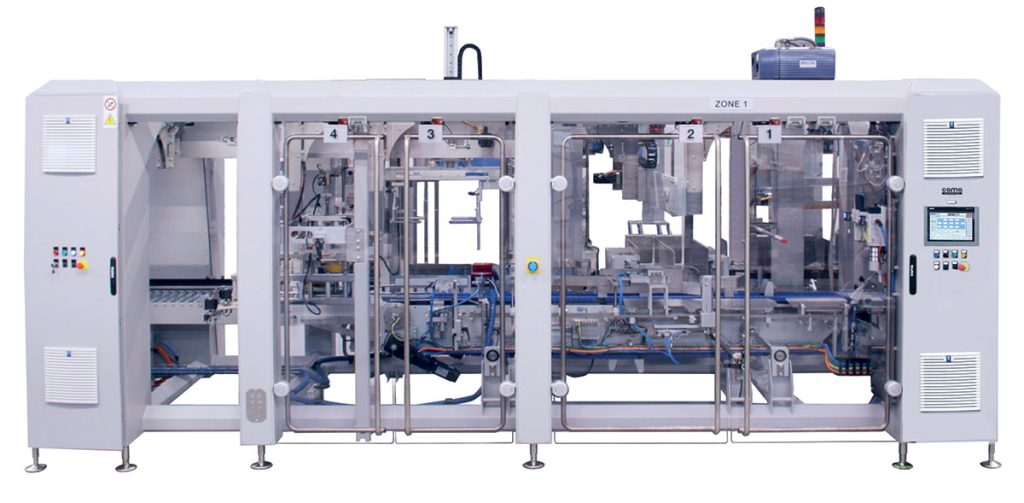

Cama’s solution is a Breakthrough Generation (BTG) monoblock system capable of receiving products from three flow-wrappers simultaneously at a rate of 900 parts per minute. Each arrival lane is managed independently in a dedicated loader unit, where a multi-race tracker system groups the products and composes the desired packaging configurations. The product groupings are then transferred to the next station for side loading into cases.

“The complexity of managing three different infeeds in one single machine requires a highly technological solution,” Borgo explains. “All units are interconnected, but at the same time independent, allowing the customer to maximize production volumes and reduce downtime.”

Industry 4.0 capabilities

The monoblock’s modular, scalable, and hygienically designed frameworks house contemporary automation solutions, including advanced rotary and linear servo technology, to deliver the flexibility and adaptability required by modern packaging operations. Its digital platform also supports full Industry 4.0 capabilities, including AR, VR, and virtual testing, training, operation maintenance, and even spares. From an operator perspective, the design offers maximum accessibility, allowing a single operator to manage the entire line.

“As a global leader, the customer was also extremely focused on sustainability,” Borgo adds. “Our solutions provide significant improvements across multiple aspects, and for this project we faced three challenges. The first was reducing plastic use, which we achieved using hot melt closure instead of tape. The second was optimizing box dimensions, achieved by developing a solution that required no further case modifications. Finally, our solution also exploited recycled-board packaging at a higher rate than the previous manual process. All these features play an important role in reducing environmental impact!”

Domain expertise

“This application is the seventh such system we’ve deployed for instant-noodle packaging,” Borgo concludes, “and is the latest in a series of different machines we’ve delivered to this customer for multiple products and applications across its many global sites. This domain experience and customer confidence play a huge role in our industry acceptance, forming a couple of the many reasons we’re seeing approaches from customers and industries worldwide. In fact, we’re seeing many of the world’s leading brands standardize on our innovative and highly agile approach to secondary packaging.”