Evolving markets require proven solutions in order to gain greater economies. Noodles may be basic, but their packaging demands certainly are not

Convenience foods are an international phenomenon, with new variants and markets constantly emerging. Many are short-lived fads, but some have stood the test of time, including the humble instant noodle. These noodles form a staple meal or snack across countless regions and demographics, offering ease of preparation and a variety of flavors and spice packets, allowing for a different variety every day of the year. The recent pandemic has also underscored the importance of tasty, easy-to-make comfort food, with some figures indicating a doubling in consumption.

“There is a massive array of market maturities all over the globe,” explains Alessandro Rocca, Sales Engineering Director at Cama Group. “Some markets are well established, such as Japan and China, but we are seeing rising demand in India and Malaysia too, both of which are overtaking China in terms of volume. Major growth is anticipated in Africa and the Philippines as well.”

Greater economies require automation

“Although diverse geographically,” Rocca continues, “all of these markets share a common need: introducing further economies by exploiting automation in their packaging regimens. The mature markets are already well served, but the growing markets—especially as companies secure a foothold—are embarking on this modernisation journey, seeking greater efficiencies.

“For some multinationals, it is a natural progression,” Rocca adds, “comprising a ‘technological cut-and-paste’ of operations from an established region to a growing region. We are fortunate to be on the supplier lists of many of these larger companies in their established markets, allowing us to learn from these installations and replicate our successes elsewhere. Our mentality and personality also make us attractive to smaller companies, leading to a noodle-driven expansion in several different regions.”

Rising demand drives need for investment

In a recent project, Cama was tasked with developing a new secondary packaging solution for one of the world’s largest food and confectionery suppliers at a brand-new greenfield site in India. The customer, seeing a 30% increase in noodle demand even before the pandemic, sought to exploit the capabilities and flexibilities of automation, calling on Cama for its expertise.

“This was a big project,” Rocca explains. “The Indian market began to flourish in 2018, and based on our experiences with the customer – for whom we installed the first noodle line 15 years ago in another country – we were asked to develop a solution for its new site, leveraging our experiences and technological evolution over the past 15 years.

“There are two approaches to this type of application,” Rocca elaborates. “Do you side load, or do you top load? Our solution specified sideloading for better product control, especially given the throughput levels. The customer had also experienced mis-packing problems with a competitor’s top-loading machine at another plant, so was not eager to face the same issues.”

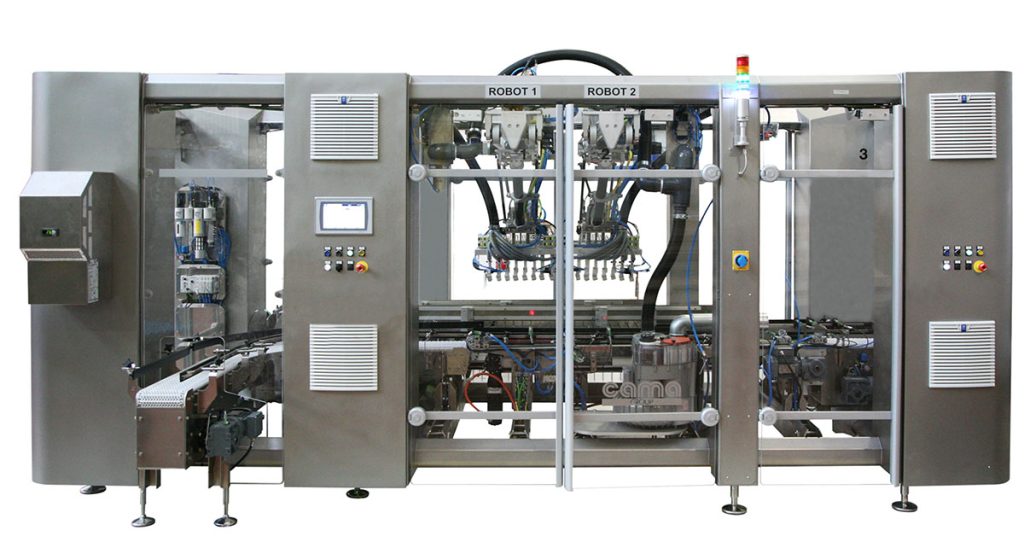

Cama’s solution comprised two Breakthrough Generation (BTG) IN Series case packers, each fed by three high-speed in-feed lines. Key figures include an infeed of 990 packs per minute and an output of 11 RSC cases per minute.

Maximum capabilities in minimum space

“Not everyone can package cleanly and successfully at this rate,” Rocca enthuses. “Space was also a key consideration. We had to combine multiple loaders feeding one machine into a limited bit of real estate. With such a high infeed rate – managed by the machine’s triple independent loaders – we also had to design in a buffer to prevent microstops. Typical buffers are built for 20 to 30 seconds; this one had to be 60 seconds!”

In operation, each infeed supplies products at a rate of 330 per feed. The product packages are turned on their edge and enter a racetrack, creating the first batch configuration. These then feed into a stacking device, assembling the product stacks. Once the packaging configuration is completed, all products are transferred into a mono-axis conveyor, which takes production from each infeed (with a slot for each) and, once full, advances them to the case packer, where a pusher pushes the noodle collations into the pre-assembled carton. The cartons are sealed using glue, tape, or both, checked for integrity, and passed to the outfeed.

“We developed a special pusher system to push the noodle packs into the cases,” Rocca explains. “Insertion of 96 packs or more has to be handled carefully, otherwise product losses that afflict top loaders can occur. The key to flexible noodle packaging is the ability to package both single and multipacks (up to 6) in the same case, with minimal intervention. Multi-infeed machines usually dislike product variation, but our IN Series solution handles 40 to 100 packs in the same case style. We’ve also developed a way to quickly adjust the loaders, keeping a complete changeover to just 32 minutes—a quick time for a machine with three infeeds and a case packer!”

Cama’s Breakthrough Generation (BTG) concept is setting the standard in secondary packaging. The machines deliver modular, scalable frameworks offering easy entry and access, coupled with a hygienic design. Within this framework, contemporary automation solutions, including advanced rotary and linear servo technology, are tightly coupled to in-house-developed robotics, delivering the flexibility and adaptability needed for modern packaging operations.

“Automation and Industry 4.0 capabilities were another important facet of this project,” Rocca explains. “Our customer is a frontrunner in deploying connected manufacturing solutions, and its size and global reach also dictate the direction many other companies follow.

“In this instance,” he concludes, “Augmented Reality capabilities were part of the wish list, something that has come to the fore over the last few months, with social distancing and travel restrictions moving almost all correspondences online. Our deployment of contemporary automation solutions makes these Industry 4.0 capabilities easier for customers to reach, and we’ve seen positive real-life results recently, proving vital for FATs, training, maintenance, and operation, all delivered and performed virtually.”